- Root cause Analysis

- Preventive Measure Strategy

- Implementation

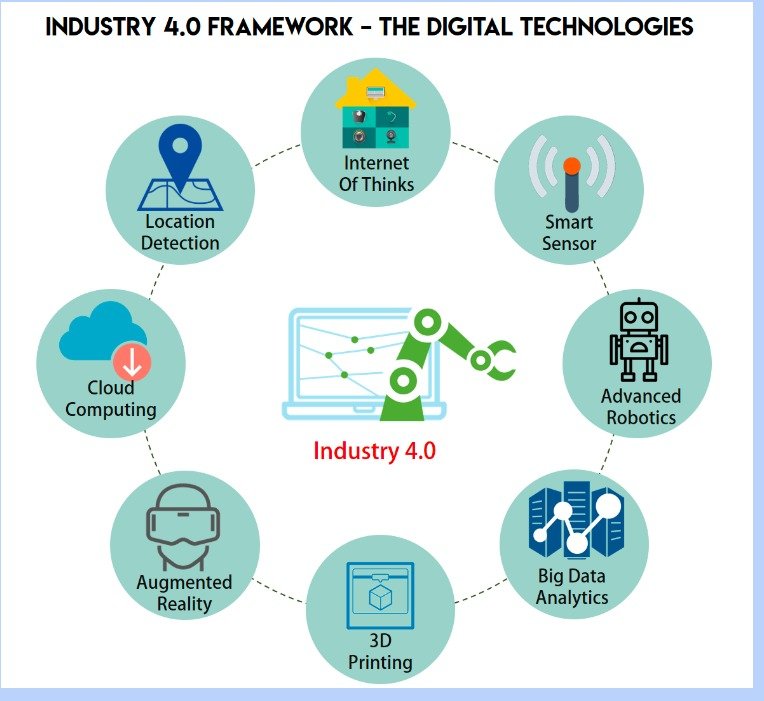

In the futuristic world of Industry 4.0, businesses are transforming how they create, build, and deliver products. Imagine a world where machines talk to each other, where everything is connected through the power of technology. This is made possible by incredible advancements like the Industrial Internet of Things (IIoT), cloud computing, artificial intelligence (AI), and machine learning.

These technologies work together seamlessly, creating a manufacturing process that's not only smart but also efficient. Factories, products, and equipment are all connected, making everything run smoothly and intelligently.

But Industry 4.0 isn't just about machines—it's about people too. It's about finding ways for humans and technology to work together in harmony. By combining the precision and speed of these advanced tools with the creativity and ingenuity of your workforce, amazing things can happen.

Imagine your team being freed from repetitive tasks, allowing them to focus on what they do best—innovating and problem-solving. With Industry 4.0, your manufacturing operations become more efficient, and your employees have the opportunity to collaborate with cutting-edge technology, preparing them for the exciting future ahead.

In this futuristic world, collaboration between humans and technology isn't just beneficial—it's essential for success.

In Industry 4.0, people come first. They're seen as valuable members, not just workers. Companies are changing to better serve their employees. It's not just about making customers happy anymore; now, they also want to make sure their workers feel valued. Bringing in and keeping the best employees is a big priority in this new way of working.

In today's connected world (Industry 4.0), everything's more linked together. Before, businesses mainly focused on making processes efficient and maximizing profits. But with big global events like Covid-19 and supply shortages, just being efficient isn't enough to stay strong. It's like having a car that's super fast but not very flexible.

Industry 4.0 extends sustainability from simply reducing, minimising or mitigating against climate damage to actively pursuing efforts to create a positive change. Sometimes referred to as ‘Net Positive,’ this goal aims to make the world a better place with companies becoming part of the solution rather than being a problem or simply paying lip-service to sustainability goals through ‘greenwashing.’

Predictive Maintenance

Enhanced Maintenance

AIML algorithms are used to sensor data from production equipment,identifying patterens that may indicate potential issues or impending failures.

Improved Quality & Productivity

Better Sustainability